PROMISE

Promise of Quality

Quality Policy

The Katayama Quality Policy and Quality Action Guidelines.

Quality Policy

Katayama Seiyakusyo creates a Quality Culture and promises to pursue safe and reliable medicine creation with a sense of pride that all of our activities ultimately bring smiles to patients’ faces.

Quality Action Guidelines

Katayama Seiyakusyo has established Quality Action Guidelines for fulfilling our

Quality Policy.

一 Comply with all regulations and contracts

一 Follow and continuously improve an effective Pharmaceutical Quality System

一 Ensure data integrity

一 Conduct quality risk management

一 Apply corrective action and preventive action (CAPA)

一 Provide continual education and training for all employees

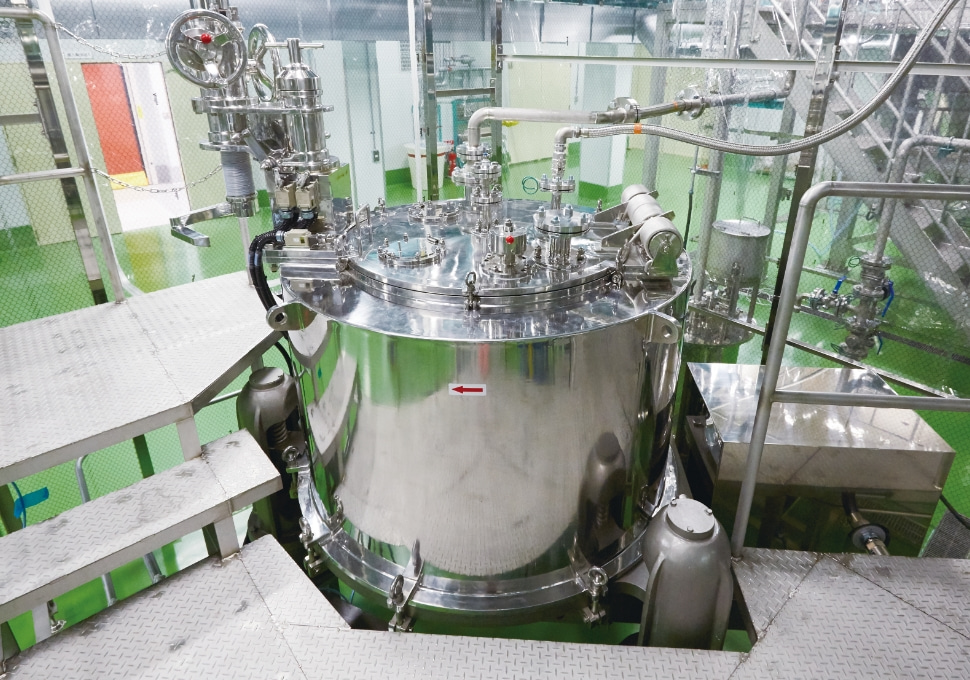

Production Equipment

Through cooperation between our Research Department and Manufacturing Department, we are able to support multi-step production for orders ranging from several kilograms to several tons. With our multi-purpose equipment, we manufacture a wide range of high-quality APIs and intermediates through cGMP-compliant production and quality control.

With the cooperation of the Research Department, we support sample work, pilot production, and high-mix, small-volume production to medium-scale production of commercial products.

| Equipement | Material | Size | Unit | |

|---|---|---|---|---|

| Reactor | GL | 1,400~2,000 L | 10 | |

| 600~1,000 L | 4 | |||

| 50~300 L | 5 | |||

| SUS | 500 L~1,200 L | 12 | ||

| 80 L | 1 | |||

| Autoclave reactor | SUS | 600 L (0.97 MPa) | 1 | |

| High-temperature reaction reactor | SUS | 700 L (~200℃) | 1 | |

| Drying equipment | Air tray dryer | SUS | 300~500 L | 7 |

| Vacuum tray dryer | SUS | 200 L | 1 | |

| Conical dryer | GL | 300~800 L | 3 | |

| Centrifuge | Top discharge type | SUS | 24 inch | 10 |

| Aflon lining | 24 inch | 3 | ||

| Hastelloy and ETFE | 15 inch | 1 | ||

| Filtration equipment | GL | 50~100 L | 2 | |

| SUS | 50~110 L | 4 | ||

| SUS | Columns | 2 | ||

| Pulverizing equipment | Soft mill | SUS | ― | 2 |

| COMIL | SUS | ― | 1 | |

| Clean room (Class 100,000) | ||||

| Centrifuge | Top discharge type | SUS | 24 inch | 1 |

| Drying equipment | Tray dryer | SUS | 500 L | 1 |

We support large-volume production of pharmaceutical intermediates and active pharmaceutical ingredients including after midterm investigating and commercial products.

| Equipement | Material | Size | Unit | |

|---|---|---|---|---|

| Reactor | GL | 8,000 L | 1 | |

| 2,000~5,000 L | 25 | |||

| 500~800 L | 3 | |||

| SUS | 1,500~5,000 L | 15 | ||

| 350 L~1,000 L | 4 | |||

| Autoclave reactor | GL | 3,000 L (0.97 MPa) | 2 | |

| 800 L (0.97 MPa) | 1 | |||

| Drying equipment | Air tray dryer | SUS | 1,000 L | 3 |

| Conical dryer | GL | 1,500~2,000 L | 4 | |

| SUS | 1,500 L | 1 | ||

| Centrifuge | Top discharge type | SUS | 30~42 inch | 11 |

| Aflon | 30 inch | 3 | ||

| Bottom discharge type | SUS | 24~36 inch | 8 | |

| Horizontal type | Hastelloy | Φ1,300mm | 1 | |

| Filtration equipment | GL | 0.13~0.5 m² | 6 | |

| SUS | 0.13~0.50 m² | 11 | ||

| Pulverizing equipment | Soft mill | SUS | ― | 2 |

| COMIL | SUS | ― | 2 | |

| Fine impact mill | SUS | ― | 1 | |

| Pin mill | SUS | ― | 1 | |

| Line Impact Mill | SUS | ― | 1 | |

| Clean room (CLASS 100,000) | ||||

| Reactor | GL | 4,000 L | 1 | |

| Centrifuge | Top discharge type | SUS | 30 inch | 2 |

| Drying equipment | Conical dryer | GL | 800 L、1,500 L | 2 |

| Other | ||||

| Pulverizing equipment, Sieving equipment, Centrifugal thin film vacuum evaporater, Ultrafiltration unit, Electrolyzer system | ||||

The 3rd building Equipment

We constructed a new building to improve production capacity in 2016. It complies with the current GMP and computer controlled systems are installed.

| Equipement | Material | Size | Unit | |

|---|---|---|---|---|

| Reactor | GL | 10,000 L | 1 | |

| 8,000 L | 1 | |||

| 5,000~6,000 L | 5 | |||

| 3,000 L | 1 | |||

| SUS | 800、2,000 L | 2 | ||

| Autoclave reactor | GL | 3,000 L (0.97 MPa) | 2 | |

| Drying equipment | Conical dryer | GL | 1,500 L、2,000 L | 2 |

| Centrifuge | Top discharge type | SUS | 42 inch | 1 |

| HASTELLOY | 42 inch | 1 | ||

| Bottom discharge type | SUS | 48 inch | 1 | |

| Filtration equipment | GL | 0.12 m² | 1 | |

| SUS | 0.5 m² | 1 | ||

| Physical Methods |

Chromatography

Spectroscopic Methods

Other Physical Methods

|

Powder property Determinations |

|

|---|---|---|---|

| Microbial Tests |

|

||

| Other |

|

Research System

Our Research Department located in the Hirakata Plant plays a central role in our contract development and manufacturing operations. The department applies our extensive knowledge of organic synthesis and scale-up technologies to meet client needs at all stages of APIs and intermediates manufacturing.

Initial Development Stage

- Synthetic route development for a compound

- Testing method development

- Lab sample synthesis

Intermediate Development Stage

- Establish API and intermediate manufacturing methods

- Synthetic route and cost efficiency improvement

- Process safety examination

- Scale-up

Final Development Stage

- Application data collection

- QRA

- Process validation

- DMF registration

The Research Department is fully equipped with various devices and equipment needed to test industrialization and manufacturing methods. Our system meets client delivery schedules and product quality specifications and is capable of addressing any issues that arise.

Main experimental devices and equipment

NMR、LC-MS、HPLC、UPLC、GC、SC-DSC、TG-DTA、XRPD、Easy Max 402 HFcal(Reaction calorimeter)、Particle Track(Real-time particle distribution measuring device)、Easy Viewer(Particle image analyzer)

GMP Compliance System

Our GMP system, constructed for strict compliance with domestic and overseas GMP and ICH GMP

guidelines for APIs, has received approval from the PMDA in Japan, the FDA in the U.S., and

regulatory authorities in Europe, and is rated highly by clients as well.

We have also created and engage a Pharmaceutical Quality System to improve the quality of

pharmaceutical products and ensure stable supply. The Quality Assurance Department and

Quality Control Department engage in all quality-related requirements independently of the

Manufacturing Division, and are fully authorized to execute GMP management.

Manufacturing management follows a strict GMP system in all processes from raw material

procurement to product shipment.

Our comprehensive system enables us to fully meet the quality standards of our clients.

Quality assurance (QA)

We carry out work related to quality assurance in strict compliance with the latest laws, regulations, rules, and guidelines from government institutions and related organizations.

Quality control (QC)

By collecting the latest information on official compendia and analytical technology, and by reflecting these in our testing and inspection, we enrich our quality management work.

Manufacturing management

From selection of raw materials to procurement and on to shipment of manufactured product, we support clients' desired delivery dates with a flexible schedule under strict GMP management.

GMP organization chart

We have constructed the following proprietary GMP organization at our Hirakata Plant and Toyama Plant.

Documentation system of GMP

From arrival of raw materials to shipment of product

Audits and Inspections

Manufacturing APIs and intermediates requires inspections by regulatory authorities or audits by clients. Both of our plants have been evaluated highly in inspections by regulatory authorities and in audits by clients.

| Organization | Period | Details |

|---|---|---|

| FDA | 2008 | GMP inspection |

| 2014 | GMP inspection | |

| 2017 | GMP inspection | |

| 2022 | GMP inspection | |

| PMDA | 2018 | GMP inspection |

| Prefectural Government | 1998 | Acquisition of pharmaceutical manufacturer license |

| 2003 | Renewal of pharmaceutical manufacturer license | |

| 2008 | Renewal of pharmaceutical manufacturer license | |

| 2013 | Renewal of pharmaceutical manufacturer license | |

| 2018 | Renewal of pharmaceutical manufacturer license | |

| 2023 | Renewal of pharmaceutical manufacturer license | |

| Clients authorities | 1997- | Over 50 audits and over 100 inspections |

PMDA : Pharmaceuticals and Medical Devices Agency

FDA : U.S. Food and Drug Administration

| Organization | Period | Details |

|---|---|---|

| FDA | 2004 | GMP inspection |

| 2016 | GMP inspection | |

| 2019 | GMP inspection | |

| EMA/AIFA | 2007 | GMP inspection |

| PMDA | 2011 | GMP inspection |

| 2012 | GMP inspection | |

| 2013 | GMP inspection | |

| 2015 | GMP inspection | |

| 2021 | GMP inspection | |

| Prefectural Government | 1988 | Acquisition of pharmaceutical manufacturer license |

| 1993 | Renewal of pharmaceutical manufacturer license | |

| 1998 | Renewal of pharmaceutical manufacturer license | |

| 2002 | Renewal of pharmaceutical manufacturer license | |

| 2004 | GMP compliance inspection for export pharmaceuticals | |

| 2007 | Renewal of pharmaceutical manufacturer license | |

| 2008 | GMP inspection | |

| 2010 | GMP inspection | |

| 2012 | Renewal of pharmaceutical manufacturer license Acquisition of veterinary drug manufacturer license |

|

| 2014 | GMP inspection | |

| 2017 | Renewal of pharmaceutical manufacturer license Renewal of veterinary drug manufacturer license |

|

| 2018 | GMP inspection | |

| 2022 | Renewal of pharmaceutical manufacturer license Renewal of veterinary drug manufacturer license |

|

| Clients authorities | 1988- | Over 50 audits and over 300 inspections |

PMDA : Pharmaceuticals and Medical Devices Agency

FDA : U.S. Food and Drug Administration

EMA : European Medicines Agency

AIFA : Agenzia Italiana del Farmaco